|

ARISTOTLE UNIVERSITY OF THESSALONIKI |

|||||||||||||||

|

|

SERVICES

The Laboratory of Machine Elements and Machine Design offers state of the art services in the field of Additive Manufacturing - 3D printing, supporting innovation and prototype design and manufacturing throughout the process from drafting till final production of components and mechanisms The offered services, include the use of additive manufacturing production of metal (EOSINT M280) and plastic (FORMIGA P110), as well as expert support in drafting, simulation and production. Additionally, various 3D scanning options are available for component digitization complementing the design procedure.

3D Metal sintering EOSINT M280 is capable of producing metal 3D parts in a variety of metals and alloys. The options include various steels, nickel alloys, CrCo alloys and Titanium. The maximum dimensions of a solid component are:(WxDxH) 250 x 250 x 330 mm

3D Plastic sintering EOS FORMIGA P110 is capable of producing plastic 3D parts in large volumes from Nylon plastic powder based on Polyamide 12 (PA12). The offered options include filled and unfilled powders suited for different applications The maximum dimensions of a solid component are (WxDxH) 200 x 250 x 330 mm

3D Scanning The HDI Advance, structured light 3D scanner,is a portable device that can produce point clouds on-site, providing fast and accurate digitization of parts and components ranging from a few mm to a couple of meters.

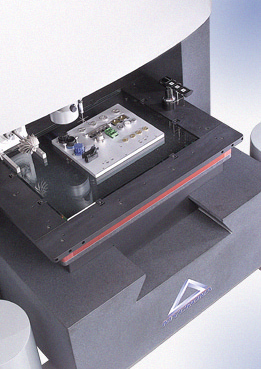

CMM Magnus of Mycrona, offers scanning using haptic and optic methods with accuracy better than 2μm for 3D and 1μm for 1D scans. The maximum dimensions of a solid component are (WxDxH) 440 x 400 x 300 mm

|

|||||||||||||||

| © 2022 |

|